Orifice Flange

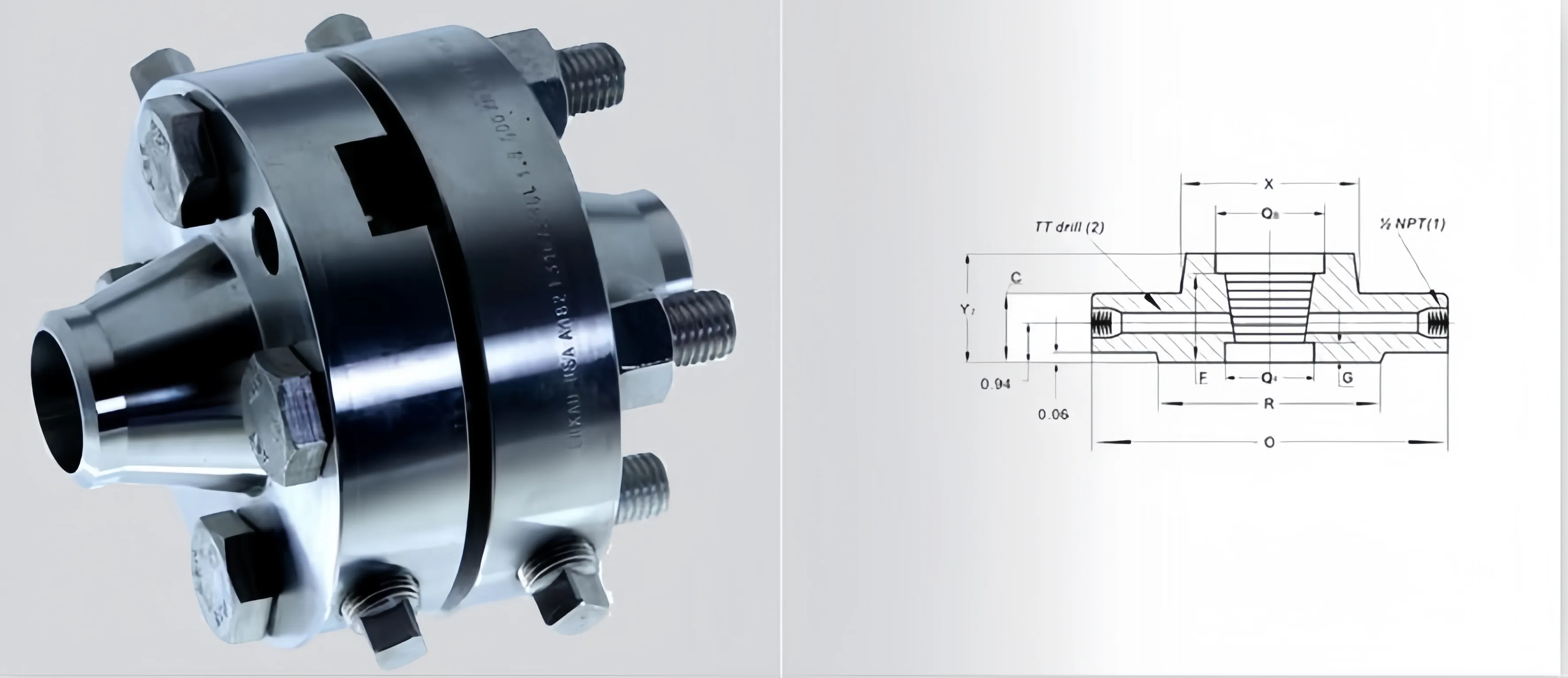

Orifice Flanges are used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline.

Orifice flanges generally come with either raised faces or RTJ (Ring Type Joint) facings.They are,for all intensive purposes,

the same as weld neck and slip-on flanges with extra machining.They have modifications of radial tapped holes in the flange ring for meter connections and orifice plate carriers for the reason of fitting meter connections.The additional bolts act as a jack to allow the separation of the two flanges to change the orifice plate or for other inspection services.

Orifice flanges are used instead of the standard pipe flanges when orifice plate or flow nozzle is used. The basic purpose for this is to measuring the flow rate of either gases or liquids in the respective pipeline.

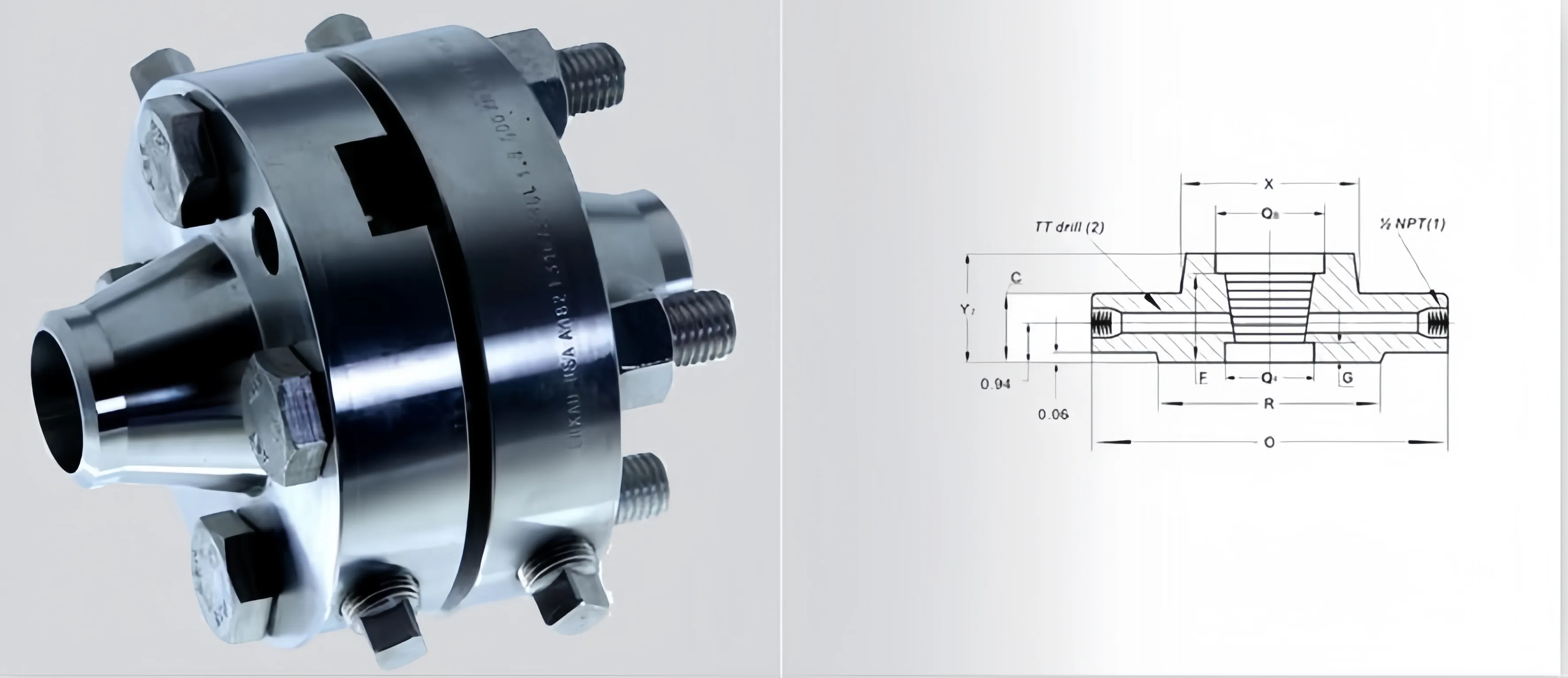

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2" NPT tappings in each flange.

ASME B16.36 covers Dimensions and dimensional tolerances from orifice flanges (similar to those covered in ASME B16.5) that have orifice pressure differential connections.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2" NPT tappings in each flange.

Size in Inch

Integral flange(Long Weld Neck Flange):3/4″-80″ DN20-DN2000

Pressure

America Series:Class 150 ,Class 300, Class 600, Class 900A ,Class 1500,Class 2500.

Europe Series:PN2.5,PN6,PN10,PN16,PN25,PN40,PN63,PN100,PN160,PN250,PN320,PN400

Flange Facing Types

America Series:Flat face(FF),Raised face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring type joints face(RJ/RTJ)

Europe Series:Type A(Flat Face),Type B(Raised Face),Type C(Tongue),Type D(Groove),Type E(Spigot),Type F(Recess),Type G(O-Ring Spigot),Type H(O-Ring Groove)

Orifice Flanges are used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline.

Orifice flanges generally come with either raised faces or RTJ (Ring Type Joint) facings.They are,for all intensive purposes,

the same as weld neck and slip-on flanges with extra machining.They have modifications of radial tapped holes in the flange ring for meter connections and orifice plate carriers for the reason of fitting meter connections.The additional bolts act as a jack to allow the separation of the two flanges to change the orifice plate or for other inspection services.

Orifice flanges are used instead of the standard pipe flanges when orifice plate or flow nozzle is used. The basic purpose for this is to measuring the flow rate of either gases or liquids in the respective pipeline.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2" NPT tappings in each flange.

ASME B16.36 covers Dimensions and dimensional tolerances from orifice flanges (similar to those covered in ASME B16.5) that have orifice pressure differential connections.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2" NPT tappings in each flange.

Size in Inch

Integral flange(Long Weld Neck Flange):3/4″-80″ DN20-DN2000

Pressure

America Series:Class 150 ,Class 300, Class 600, Class 900A ,Class 1500,Class 2500.

Europe Series:PN2.5,PN6,PN10,PN16,PN25,PN40,PN63,PN100,PN160,PN250,PN320,PN400

Flange Facing Types

America Series:Flat face(FF),Raised face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring type joints face(RJ/RTJ)

Europe Series:Type A(Flat Face),Type B(Raised Face),Type C(Tongue),Type D(Groove),Type E(Spigot),Type F(Recess),Type G(O-Ring Spigot),Type H(O-Ring Groove)

1. Materials:

Carbon Steel: ASTM A105, ASTM A350 LF1, LF2, LF3, A36, 16Mn, etc

Stainless Steel: ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Alloy Steel: A182 F1, F5, F9, F11, F12, 22, F22, F91, etc

Duplex Stainless Steel: ASTM A 182 – F51, F53, F55, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950.

Copper Alloy Steel: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600, C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

Nickel Alloy: ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

1. Materials:

Carbon Steel: ASTM A105, ASTM A350 LF1, LF2, LF3, A36, 16Mn, etc

Stainless Steel: ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Alloy Steel: A182 F1, F5, F9, F11, F12, 22, F22, F91, etc

Duplex Stainless Steel: ASTM A 182 – F51, F53, F55, S31803, S32205, S32550, S31254, SMO254, S32750, S32760, S32950.

Copper Alloy Steel: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600, C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10), C 71500 ( CU -NI- 70/30)

Nickel Alloy: ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3 ), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

For detial dimensions and catalogue of Reducing Flanges please contact with us now sales@attpipeline.com

2. Standards:

ASME ANSI B16. 5, ASME ANSI B16. 47. API 605, API 6L. MSS SP 44 CSA Z245. 12 EN1092-1, EN1759-1. DIN28115

BS1560, BS 4504, BS 10. AFNOR NF E29-200-1 ISO7005-1 AS2129 JIS B2220 UNI 2276. UNI 2277. UNI 2278. UNI 6089. UNI 6090

2. Standards:

ASME ANSI B16. 5, ASME ANSI B16. 47. API 605, API 6L. MSS SP 44 CSA Z245. 12 EN1092-1, EN1759-1. DIN28115

BS1560, BS 4504, BS 10. AFNOR NF E29-200-1 ISO7005-1 AS2129 JIS B2220 UNI 2276. UNI 2277. UNI 2278. UNI 6089. UNI 6090